Tel: +86 13862761681

Email: [email protected]

Tel: +86 13862761681

Email: [email protected]

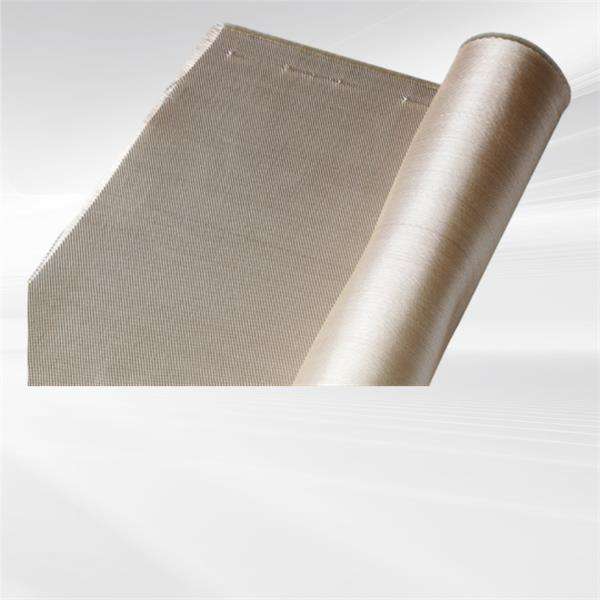

Fiberglass fabric is a wonderful material, with wide applications in the reinforcement of various items for different industries. Its special attributes provide more than a durability boost - they also enhance the structural qualities of many substrates. One of the main benefits when using fiberglass fabric is that it's fairly light as compared to certain other materials and heat-resistant properties. It also features corrosion resistance, durability, and great mechanical strength thus making it a popular material in the world of engineering.

This non-woven material uses continuous fibers that are placed in a fabric-type orientation. The flexibility of FRP composites has encouraged its use in industries like marine, aerospace and automotive amongst others even to wind energy. Fibreglass tissue is widely available in different forms such as chopped strands, woven fabric; mat and roving. The tissue form is one of the most common types of reinforcement materials used amongst these variations.

There is a very wide range of fibreglass tissue types available in the market to satisfy different necessities and requirements. The type is chosen based on the intended application, or desired mechanical properties. There is fibreglass tissue in different weights, with binder contents and finish; the user has lots of options to choose. The fibreglass meshes are mainly of three types; standard, binder and composite styles.

This coating or binder-free fibreglass cloth is sometimes called standard tissue and used for any open-molded process where resin systems actually hold the glass in place. On the other hand, bindered fibreglass tissue is made with a bonding gum which increases its performance: increased strength, minimized loose fibers and better drapability while lessening interfiber abrasion. This type is often used as an insulation in electrical applications.

The production of engineered composite materials, especially for the aerospace industry have evolved and currently a combination structure has come into existence known as Composite fibreglass tissue.

An increase in the use of fibreglass tissue across construction and auto industries has attracted a flurry of manufacturers, making it more likely that high-quality options are available. Key industry participants include Owens Corning, Jushi Group and Saint-Gobain among others.

The company, Owens Corning is a multinational corporation that manufactures and supplies insulation, roofing, and fibreglass products. They supply fibreglass tissue for construction, marine, transportation and aerospace industry across the globe.

Jushigroup was a world-class manufacturer of fiberglass products, including fiber yarns,direct roving chopped strands and fibreglass tissue. They are devoted to strict quality control systems and modern technology for the fabrication of top-grade products.

PPG Industries is the global supplier of paints, coatings, glass and has a diverse fibreglass tissue products group in its name delivering various applications. Known for durable, wet strength and chemical resistance properties - tissue products they manufacture are from 100% recovered fibers.

For instance, the global in the building materials and high performance materials market-Saint-Gobain has developed fiberglass tissue solutions designed for thermal insulation of HVAC systems, energy-efficient housing applications as well as Automotive to name a few.

Calling it fibreglass tissue should mean a lot of types and features which could make anyone get confused. This involves factors such as determining the mechanical properties that will be needed, in addition to application conditions, resin system type and price.

The weight of the tissue has an effect on its mechanical properties such as strength and stiffness. Heavier tissue may be stronger but it might not have the flexibility necessary for some uses. Different tissues have different compositions of binding agent that influence adhesion qualities and resin levels which will secure into place better.

Among these, fibreglass tissue is widely used in a variety of industries, and with the help of its un ique characteristics, it has greatly promoted th e development in the construction sector. Its flexibility and durability have led to it becoming an appealing reinforcing structural element, with fine expectations in constructions.

Fibreglass Tissue is used in construction applications for roof insulation, wall insulation and floor Insulation. The material provides excellent thermal and sound insulation characteristics, backed by good resistance to the environment. Additionally, it improves the load bearing capacity of structural elements such as beams and columns.

Thus, the fibreglass tissue convinces as an engineering material with a number of advantages. This is a material that has wide application in various industries because of its lightweight, heat resistance properties and can perform at high temperature range. Fibreglass tissues come in various flavours, types with many products to choose from available but the correct type of tissue must be chosen for a specific project. These significant applications across industries such as construction, automotive, marine and aerospace highlights a lucrative horizon for the material in building & development sector.

Renwu fibreglass tissuean experienced and trustworthy global supplier glass fiber weaving technology, which has been deeply involved in field of glass fiber for over 25 years.With experienced engineering team, we're capable customizing material, size thickness, as well as the packing bags our customers.

operate a self-sufficient chain industry-leading fire blankets which produces glass fiber fibreglass tissuefabric making fireproof items ourselves.QCQA team will perform strict inspections on products from raw materials fiberglass cloth, before moving on to final product packing shipping.

ISO90012015 certified company has two factories, which established in 2009 fibreglass tissueover 15 years of experience. top-quality items sold well in over 30 different regions countries which include China, the United States America, Europe Asia.

support team is available 24 hours day, 7 days a week. team, always provide highest level of support to customers from the global market. annual production capacity exceeds 500,000 square meters. Our glass fiber fabric is available in widths up to 2 meters the maximum lengths 500 meters. We will fibreglass tissuemeet your needs.