Tel: +86 13862761681

Email: [email protected]

Tel: +86 13862761681

Email: [email protected]

Do you know what welding is? Welding is the process of joining two pieces of metal together, there are different kinds but we are just getting into this. All of this is a critical process in many industries including construction and manufacturing. Although, the danger of welding process's can be risky sometimes if done carelessly. Welding can make floor puzzy that combustion and catch fire. Thankfully, there is a great tool that helps to keep everything safe when you are welding: the fireproof welding blanket.

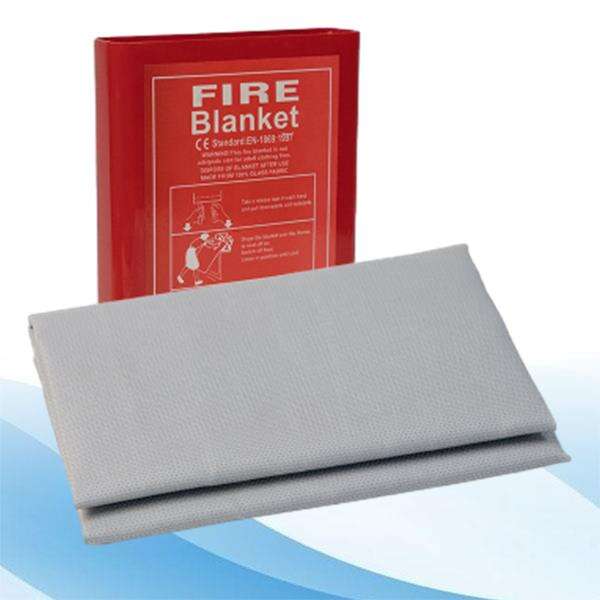

A fireproof welding blanket is a densely-woven textile that is flame retardant. The thermal blanket can be used at very high temperatures from 1,800°F (982°C) downwards. Fiberglass is by far the most common material used in constructing a welding blanket, and besides being extremely fireproof it also has several other advantages. Fiberglass is a sturdy material that does not ignite easily During welding, whereas its durability makes it appropriate to protect surfaces.

The blanket can be used by laying it over whatever surfaces you would rather not fill with spatter, sparks and other hot junk from weldivism. They can also be used to wrap equipment or materials that need heat protection when welding. It is through this, that you may have your workspace remain safe and be prevented from functioning as fire hazards.

Welding is one type of activity that could be dangerous. It can not only burn your skin, it also poses the risk of starting fires - injuring people or destroying property. That is why it becomes essential for us to use a quality fireproof welding blanket. Some of the main features a reliable welding blanket must have in order to work are:

Vermiculite Treated Fiberglass Welding Blanket: A fiberglass welding blanket with a vermiculite coating. This finish is highly protective and fire retardant. Even more so, able to withstand temperatures of 1.500°F (815°C), this is called for some still previewed usages because it will give you the security that we are a competitive option from most platforms in our market niche.

Fiberglass Material: Most popular for welding blankets, It is cost-effective, light-weight and versatile. It can, however, outgas some irritating fumes when heated and as such is not advised for welding in confined spaces nor by someone with respiratory issues. Alternatives, such as carbon fiber or silica and ceramic fibers offer higher resistance to heat along with lower toxic properties making them safer.

Warmth: How the warm or cold a blanket is and their ability to absorb heat.Thickness : The thickness of the weft affect how well blankets can insulate warmth from spreading away.. The more protection it provides, the harder it is going to be for you handle and store these blankets if they are thicker. Look for a versatile intermediate concerning width and usefulness to accommodate your particular person.

24 hours support and after-sales staff, always offer the best services for clients in the international market. annual production capacity is fireproof welding blanketthan 500,000 square meters. thickness of our glass fiber fabric can reach up to 2 meters, the maximum length can be up to 500 meters, try best to satisfy your needs.

QCQA team will be examining products at every stage beginning with raw material, through fireproof welding blanketcloth and then to final product.

Renwu Fiberglass, professional reliable world-class manufacturer fireproof welding blanketfiber weaving technology, which has been involved the field of glass fiber for over 25 years.With experienced engineering team, we're able to customize the material, size or thickness, as well as packing bag our customers.

ISO90012015 certified manufacturer operates two factories, which fireproof welding blanketin 2009, has more than 15 years experience. Our top-quality products sold well more than 30 different countries and regions, including China, the United States America, Europe Asia.