Tel: +86 13862761681

Email: [email protected]

Tel: +86 13862761681

Email: [email protected]

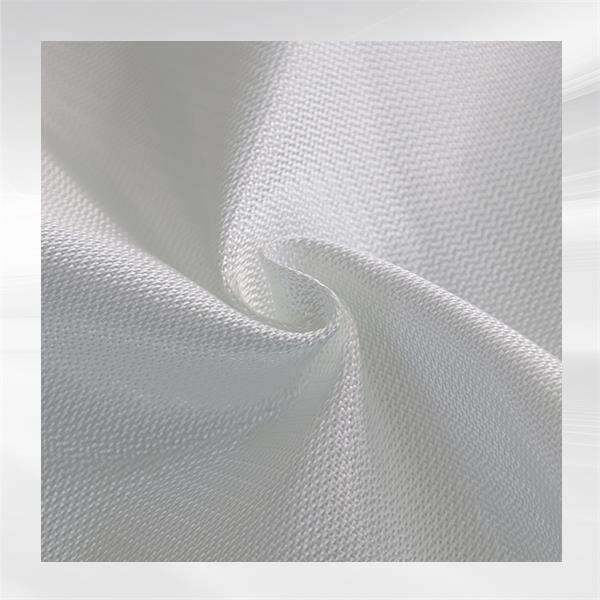

Woven fibreglass truly is amazing craftmanship, both in terms of its strength and how flexible this material is. The material is an impressive part that's formed by weaving hair strands of glass together to form a textile-like substance it can be molded into various shapes easily. With such broad applicability, from manufacturing to construction and everything in between, its versatility is unmatched.

The woven fibreglass is truly an engineering masterpiece because it simply does not get any atomical better than this. Making molten glass into thin fiber through the process of weaving becomes a material with an immense strength build but unexpectedly light weight and soft. This unique blend of tensile strength and flexibility has made woven fiberglass a popular choice for use in the manufacture of automotive parts, boats even aircraft. In addition to the entertainment factor, it is also resistant from being eaten by rust or moisture due to its built out of glass; this makes desirable for other applications as well.

However, the strength and durability of woven fibreglass are only two of its phenomenal benefits. It has a weight that is like no other, it works lovely in an application where keeping the number of pounds down weighs heavy on your mind and due to how light this stuff is you can bet your bottom dollar its going to withstand daily abuse. Further benefits include its natural moisture- and corrosion-resistant glass composition; this means that borosilicate glass is ideal for outdoor applications, as well as in tough environments where hardness matters. Moreover, the pliability of woven glass enables it to be shaped and molded into any form so that countless products such as car parts, boats or airplanes can easily produced with this material.

Modern Uses for Fabric Glass Productionmaciej Modern applications will keep doing this.

The tensile and thermal properties of woven fibreglass make it suitable for many individual manufacturing processes where the monofilaments inside glass facilitate liquid resin to move around along with forces being applied and can also increase the strength require when a filament winding applies. Woven fiberglass has the potential to improve many things from sporting gear like hockey sticks and golf clubs, all the way to developing strong yet lightweight prosthetics at a fraction of what it cost in medical. This is a contributing factor to why it is valuable in automotive parts such as body panels and hoods, ensuring tough base layers for producing durable abrasion-resistant vehicles.

The flexibility and durability of woven fibreglass has been put to the test in different aspects such as construction and architectural projects, proving its ease of integration. Woven fibreglass, whether employed in roofing solutions that necessitate lightweight but robust substances or insulation applications requiring fast installation with fire resistance all of this we get from woven fibreglass. Additionally, the role it plays in generating intriguing textures and patterns on building facades makes itself a great option for architects and builders looking to explore design ideas.

Since technology will keep on progressing, woven fibreglass has become a significant material in loads of industries and it guarantees more advancement soon. Investigation into the possibilities of 3D printing with woven fibreglass materials suggest that this might open up new means by which lightweight and durable products can be created. It also boasts a long-lasting quality that helps promote sustainable manufacturing practices when not frequently discarded. Engineers are still playing around with ways to use woven fibreglass so the future can only be full of new and genius applications.

By all this, woven fiberglass turns out to be an awesome material with endless potential. Its strong, lightweight properties and versatility make it popular in a variety of industries from advanced manufacturing to construction and architecture. Woven fibreglass has a bright future ahead, as new innovations and implications are set to completely transform how it will mold industries in the years following.

are a self-sufficient fire blanket industry chain manufacturing glass fiber weaved fabric, woven fibreglassfireproof items ourselves.QCQA team will perform strict inspections the products beginning with raw materials, through fiberglass cloth, then the finished product, and packing shipping.

support team is available 24 hours day, 7 days a week. team, always provide highest level of support to customers from the global market. annual production capacity exceeds 500,000 square meters. Our glass fiber fabric is available in widths up to 2 meters the maximum lengths 500 meters. We will woven fibreglassmeet your needs.

ISO90012015 certificated manufacturer with 2 factories , founded 2009 with more than 15 years experience.premium woven fibreglasssold extensively in over 30 countries regions, such as China the United States, Middle East, Europe, and Asia.

Renwu Fiberglass an experienced and trustworthy global manufacturer glass fiber weaving industry, which has been woven fibreglassinvolved in the field glass fiber for over 25 years.With our skilled engineering team, we're able to customize material size, thickness, and packing bag our customers.