Welding blankets are so essential tools that used in welding process. They protect the welder from harmful fire and sparks that may come while welding. Welding Blankets also make sure that the part of you around it does not burn making them absolutely necessary for safe measures.

The available options of welding blankets; Both types have their unique characteristics and are thus suitable for different kinds of works. Here's a more detailed look at some various welding blanket selections.

A Guide to Welding Blankets

There is a large variety of welding blankets available, which can be made from many different types of materials and come in all sorts of shapes and sizes. The key is to select the right welding blanket for your intention on a project. The proper welding jig will determine how smooth and stable your technique becomes, thereby adding to the quality of both safety and effectiveness during the job.

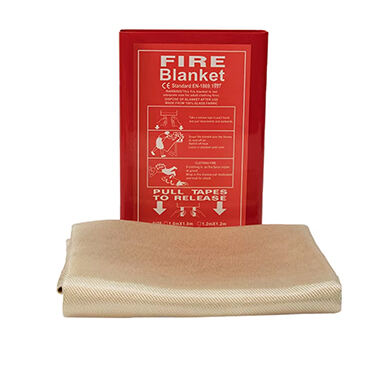

Fiberglass Welding Blankets

The following are some of the most popular welder blankets that you can get: Fibreglass welding blankets They use fiberglass strands that are woven together with a special material. A good quality fire blanket is capable of withstanding high temperatures, and it works wonders to keep the people safe as well as prevents other items in its vicinity from catching on sparks and flames.

Silica Welding Blankets

If you are doing very hot welds, Silica welding blankets would be another good choice. Constructed from silica fibers, these blankets can resist 1800°F and are also lightweight and flexible to effortlessly handle smaller or difficult-to-reach areas.

Carbon Fiber Welding Blankets

Carbon Fiber Welding Blankets are the best choice for you if you are doing welding jobs that need maximum heat resistant. These blankets hold up to 3000°F and are also chemical resistant, meaning you can use them again without losing effectiveness.

Welding Blankets Vermiculite Coated

Vermiculite coated welding blankets are manufactured with fiberglass and there is an additional special coating of vermiculite. This coating helps to fireproof them even further. While these things can withstand temps of (up to) 1500°F, they also insulate well enough to keep them cool.

Ceramic Fiber Welding Blanket

The ceramic fiber welding blankets are the most heat resistance type of all, These are made of ceramic fibers and can carry up to 3000°F by temperature, they also tend to be very lightweight and resistant towards chemicals making them safe.

Types Of Welding Blankets

Best Welding Blankets for Multi-Use

Works as a welding curtain, but with the added advantage of pulling it over your head. Available in a range of materials, sizes and textures they provide great assistance when it comes to welding as well as plumbing automotive repair or construction.

Welding Curtains

Because welding can cause dangerous light and sparks to occur, so the curtains used for this purpose are known as welding curtains. Made of high-quality coated vinyl these curtains are strong, fire-proof resistant to sparks and UV rays. They come in a variety of different colors and sizes but can also be tailor-made for you!

Flame-Resistant Tarpaulins

Flame-resistant tarps are perfect protecting equipment and other items from heat, fire or errant sparks. They are a type of tent made from fiberglass woven tarpaulins that have been coated with both heavy iron oxide and vermiculite. They are waterproof and resistant against UV rays, meaning they last long.

Selecting the Ideal Welding Blanket

There are various key considerations for you to think about when choosing the best welding blanket. Think about the material of the blanket, its size, texture and density to determine how much heat resistance your blankets possess. They are the things that determine how good or bad a particular blanket may perform during your welding work.

For example, if your work includes a lot of high temperatures with which you come in contact during the welding process; it is natural to want something that can hold up against those extreme heat levels. Also, if the job is in a restricted space you will need to look for portable and versatile blanket which can adapt easily into tight areas.

Another major concern is how easy it is to use and store the blanket. While some welding blankets are easier to roll up or fold, others may be more cumbersome and require extra storage solutions.

Comparing Welding Blankets

Using a welder blankets are made from various methods discussed at length in this resource and the comparison among them would help you to choose the best one. Take a closer look on the specifics of each blanket such as level to which they can resist heat, flexibility provided by them weight you will feel while using it and last but not least insulation qualities.

Fiberglass blankets are a good example of how you can use them to protect your home but not yourself, and they work well in this way against sparks and flames. 2) Silica Blankets: These are flexible and lightweight, perfectly designed for high-temperature environments. As a blanket, carbon fiber is able to withstand very high heat and has excellent chemical resistance. The coating on vermiculite-coated blankets enhances their ability to withstand fire, while ceramic fiber is your option for high heat.

So, in conclusion, getting the ideal welding blanket definitely issues when it comes to security and also performance during your welding job. The primary consideration you should make is to choose a blanket that meets your overall heat resistance, flexibility and the most common usual need. The following types of welding blanket, along with their special features should provide you an adequate understanding for selecting the best kindd of a welding blanket and help you complete your intended goal as flawlessly as possible.

EN

EN